Why Steel Grade Beats Thickness: The Strength of Spindo Hollow GI & STKR 400

Beyond Thickness: The Structural Reality of Hollow GI

In light construction applications such as ceiling frames, canopies, partitions, and other structural framing systems, many people still judge hollow sections mainly by thickness. However, the strength of hollow GI is not determined by thickness alone. A more important factor is the steel quality standard used in production.

This matters because even lightweight frames are still required to carry loads–both static loads and long-term loads over time. If the steel quality does not meet the proper standards, the risk of problems such as bending, sagging, or structural failure can increase. That is why choosing GI hollow section with a clear and verified quality standard is an important step to improve safety and durability.

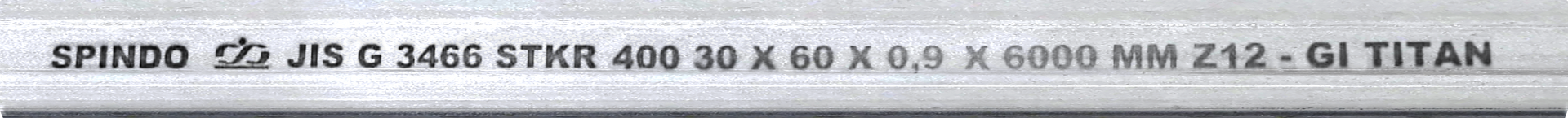

One of the key reasons why hollow GI SPINDO offer more reliable strength is because they meet the STKR 400 standard.

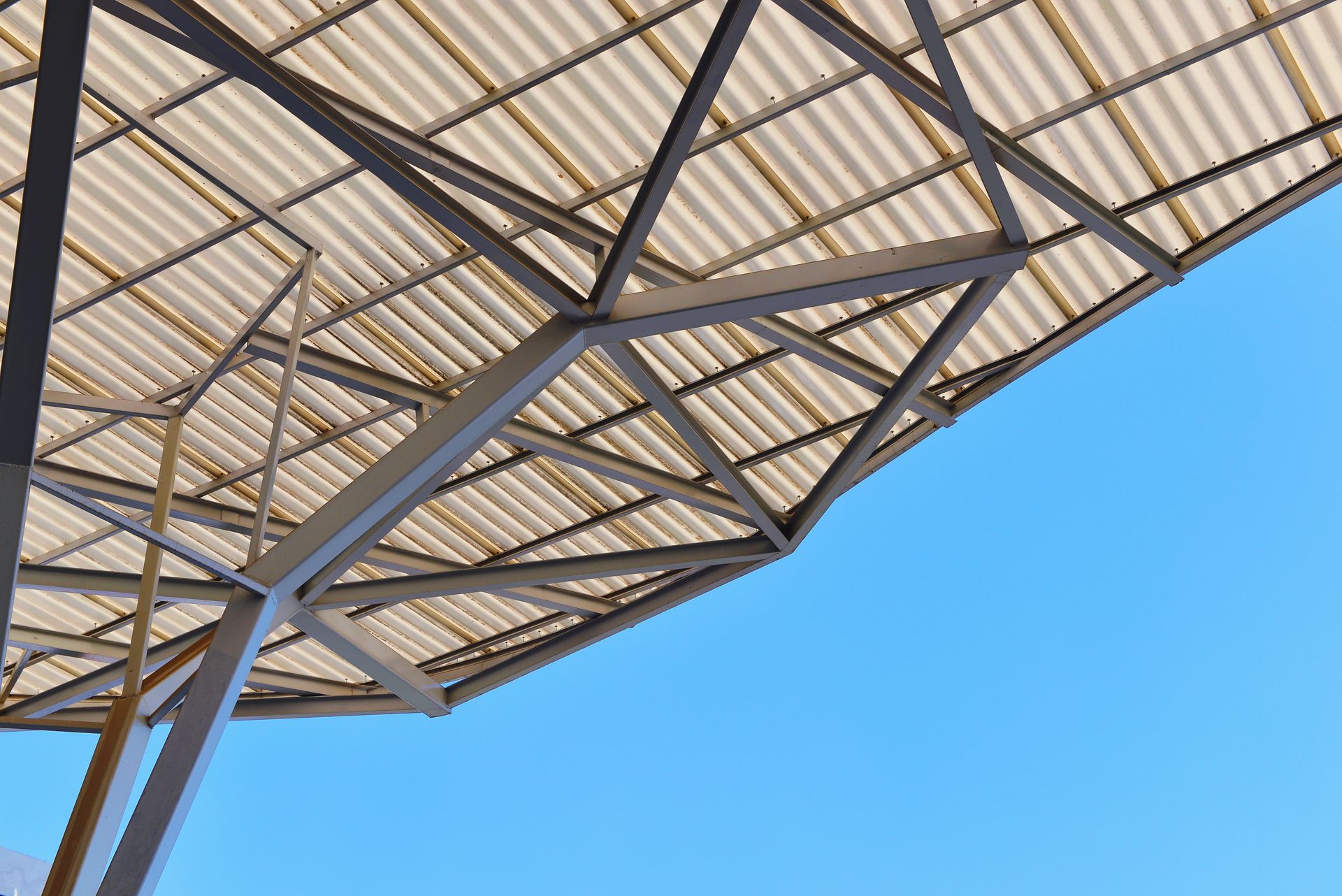

Hollow GI Application

What Is STKR 400 for GI Hollow?

STKR 400 is a structural steel quality standard for square and rectangular steel tubes (hollow), based on the JIS (Japanese Industrial Standards). This standard is used to ensure that hollow sections meet minimum mechanical requirements suitable for light structural applications.

Hollow GI that comply with STKR 400 meet minimum mechanical requirements, including:

- Tensile strength of around 400 MPa;

- Mechanical properties tested according to the standard;

- Consistent material quality during production

In other words, STKR 400 ensures that the hollow section has measurable and verified strength properties.

Why STKR 400 Matters for Hollow GI Strength

The strength of a hollow is mainly influenced by two key mechanical properties:

- Tensile strength, which indicates how much pulling force the material can withstand before breaking. The higher the tensile strength, the better the material can handle working loads and stress in construction applications.

- Yield strength, which defines the point where the material begins to deform permanently. In applications such as ceiling frames and canopies, yield strength is especially important because it is closely related to long term performance. Materials with low yield strength may bend or sag more easily over time.

Hollow GI that meet the

STKR 400 standard generally offer

more stable

mechanical performance for light structural applications. This means hollow strength

is not only about thickness, but also about the

steel grade and quality standard behind it.

Hollow GI Strength Is Not Only About Thickness

Thickness does affect stiffness. However, in real world construction, a thicker hollow section is not always stronger if the steel quality is unclear or inconsistent. A standardized product such as STKR 400 provides assurance that the material meets minimum strength requirements. This makes the performance more predictable and safer for use in light structural framing.

Why Choose Hollow GI SPINDO?

Hollow GI SPINDO are produced to meet the STKR 400 standard, offering several practical advantages for construction:

- Strength properties suitable for light structural applications;

- More consistent material quality;

- Better stability for ceiling frames, canopies, and partitions;

- A galvanized coating that helps protect against corrosion.

With a

clear quality standard, the risk of long-term deformation and strength reduction can be minimized.

In addition, the galvanized coating improves corrosion resistance, especially in humid environments or semi outdoor applications.

Hollow GI SPINDO Pipes

Conclusion

The strength of Hollow GI SPINDO is not only about thickness, but also about steel quality and compliance with the STKR 400 standard. This standard ensures the material has measurable strength properties suitable for light construction application.

Choosing a standardized hollow is an important step to improve structural safety, increase frame stability, and support long-term durability.