Choosing Stainless Steel for Industry, What to Look for?

Stainless steel is one of the most popular materials in various industries due to its corrosion resistance, strength, and attractive appearance. However, choosing the right stainless steel for industrial needs is not as easy as one might think. There are many factors that you need to consider to ensure that this material meets all the requirements and delivers the best performance. Here are some important things to consider when choosing stainless for industrial applications.

Also read: Get to Know More About Stainless Steel and Its Benefits

Tips for choosing Stainless Steel

Types of Stainless Steel

Stainless is available in many different types, each of which has specific characteristics and uses. The three main types of stainless often used in industry are:

1. Austenitic

This type is most common and is known for its good corrosion resistance as well as its ability to remain strong at high temperatures. Examples are the 304 and 316 series, which are widely used in the food and beverage, pharmaceutical, and kitchenware industries.

2. Ferritic

Ferritic stainless has good corrosion resistance and resistance to oxidation at high temperatures. However, this type is less ductile compared to austenitic. An example is the 430 series, which is often used in automotive and home appliance applications.

3. Martensitic

This type is known for its high strength and hardness. However, its corrosion resistance is lower compared to the other types. Examples of martensitic stainless are the 410 and 420 series, which are often used in surgical tools and knives.

Also read: Differences in 5 Types of Stainless Steel Often Used in Industry

Environmental Conditions

The environmental conditions in which stainless will be used greatly influence the selection of material type and grade. Some environmental considerations include:

1. Exposure to Corrosion

Highly corrosive environments such as marine environments or environments with aggressive chemicals require stainless with high corrosion resistance, such as grade 316.

2. Temperature

Applications that require stainless to operate at high or low temperatures require a type that can maintain its mechanical properties at those temperatures. For example, austenitic stainless is generally more resistant at high temperatures.

3. Humidity

High humidity environments also require stainless with good corrosion resistance.

Production Process

The production process in industry also determines the most suitable type of stainless to use. Some production processes require materials that can be easily formed, welded, or cut without losing their mechanical properties.

1. Welding

If the application requires welding, choosing a stainless with good weldability is essential. Austenitic stainless is usually easier to weld compared to other types.

2. Cutting and Forming

Softer, malleable stainless will reduce production costs and increase efficiency.

Strength and Durability Requirements

Depending on the specific application, the need for strength and durability of stainless can vary. For example, in the construction industry, stainless steel with high strength and resistance to heavy loads is necessary. On the other hand, in the food and beverage industry, resistance to contamination and ease of cleaning may be top priorities.

Cost and Availability

The cost of stainless and its availability in the market are also important factors to consider. While high-specification stainless steel may offer better performance, the cost can be much higher. Therefore, it is important to find a balance between the cost and the benefits gained.

Also read: How to Calculate Stainless Steel Needs and Prices for Your Project

Selecting stainless steel for industrial applications requires an in-depth understanding of the types of materials available, environmental conditions, production processes, as well as the specific needs of the application. By considering all these factors, you can ensure that the stainless chosen not only meets technical needs but is also economically efficient. Taking the right decision will help in improving the performance, efficiency, and longevity of the product or infrastructure that uses stainless steel. Stainless is a long-term investment, and choosing the right material can bring great benefits to the continuity and success of your industrial operations.

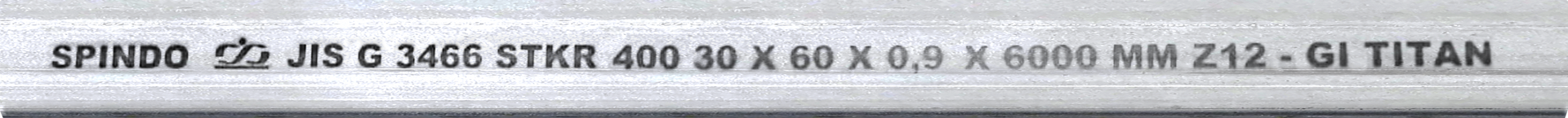

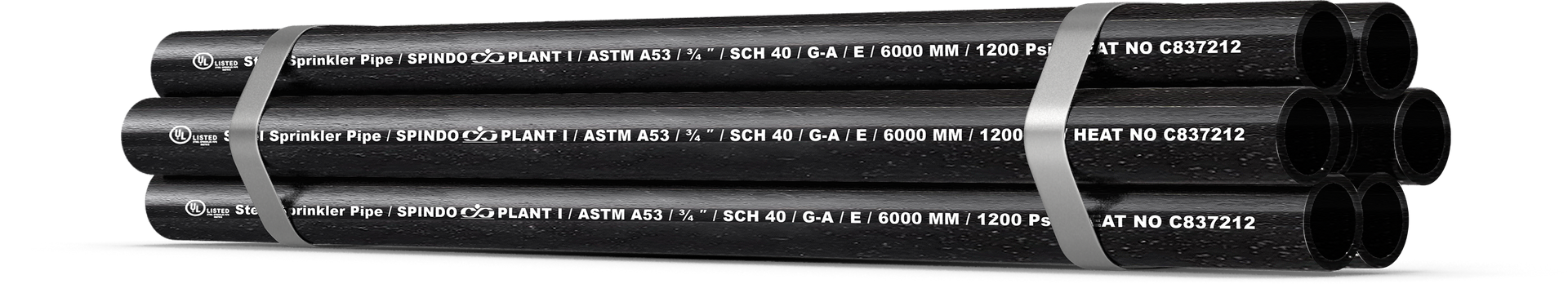

If from the series of tips above you are considering buying austenitic, it is recommended to buy from an experienced steel pipe manufacturer, such as SPINDO. As the largest steel pipe manufacturer in Indonesia with extensive experience in producing a wide range of steel pipes, tubes, and other related products, SPINDO offers austenitic stainless steel grades 304 and 316 that are ideal for various industrial applications, ranging from ornamental tubes and industrial pipes.

SPINDO provides a wide range of sizes and specifications of austenitic stainless steel to meet your needs. SPINDO's team of experts is ready to help you choose the right product for your application. Contact SPINDO for reservations or further questions by clicking the WhatsApp icon below.