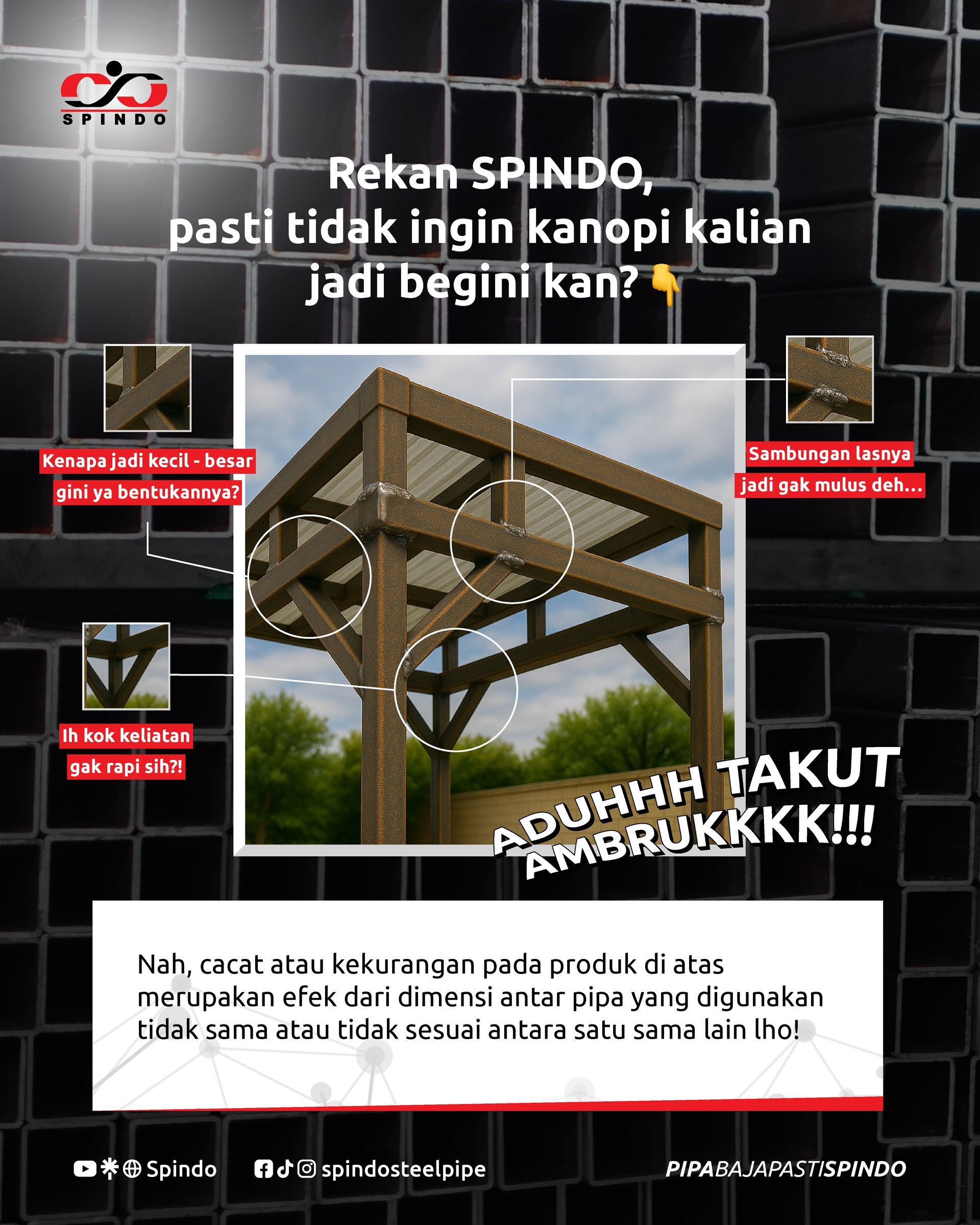

Don't Build The Bad Canopy: Recognize The Importance of Dimensional Accuracy in Hollow GI

Common Problems in Canopy Installation

Canopy installation often looks simple, but in reality requires high accuracy, especially in material selection. One of the main causes of less than optimal canopy results is the use of

Galvanized Hollow Pipe (GI) with

imprecise dimensions.

Common problems that often arise in the field include:

- Pipe connections that do not fit.

- Construction shapes that look asymmetrical.

- Uneven joint surfaces.

- Construction that feels unstable or even dangerous.

These errors mostly come from

dimensional mismatches between the Hollow Pipes used, either due to large tolerance differences or inconsistent production quality.

Impact of Hollow with Inconsistent Dimensions

When hollow pipes do not have good dimensional accuracy, the impact can be very significant on the entire project. Some of the consequences include:

- Untidy and unaesthetic finish

Installation looks messy, reducing the visual value of the building.

- Misaligned and unsound joints

The structure becomes vulnerable and less secure.

- Longer working time

Workers have to manually re-cut and adjust each joint.

- Increased cost

The need for additional materials and extra labor time increases expenses.

- Reputation at stake

If used in property or commercial projects, poor installation quality can affect customer confidence.

Solution from SPINDO: Hollow GI with High Accuracy

SPINDO presents a real solution through Hollow GI products manufactured with technology and a strict quality control system, thus providing:

- Actual and consistent dimensions

Each SPINDO Hollow GI rod is made with high accuracy so that they match each other and facilitate the installation process.

- Very minimal dimensional tolerance

The difference between sides is kept as small as possible so that the connection between pipes remains precise and strong.

This advantage is very helpful for contractors and builders in ensuring a neat, fast and efficient final result.

Proof of Accuracy: Testable by Yourself

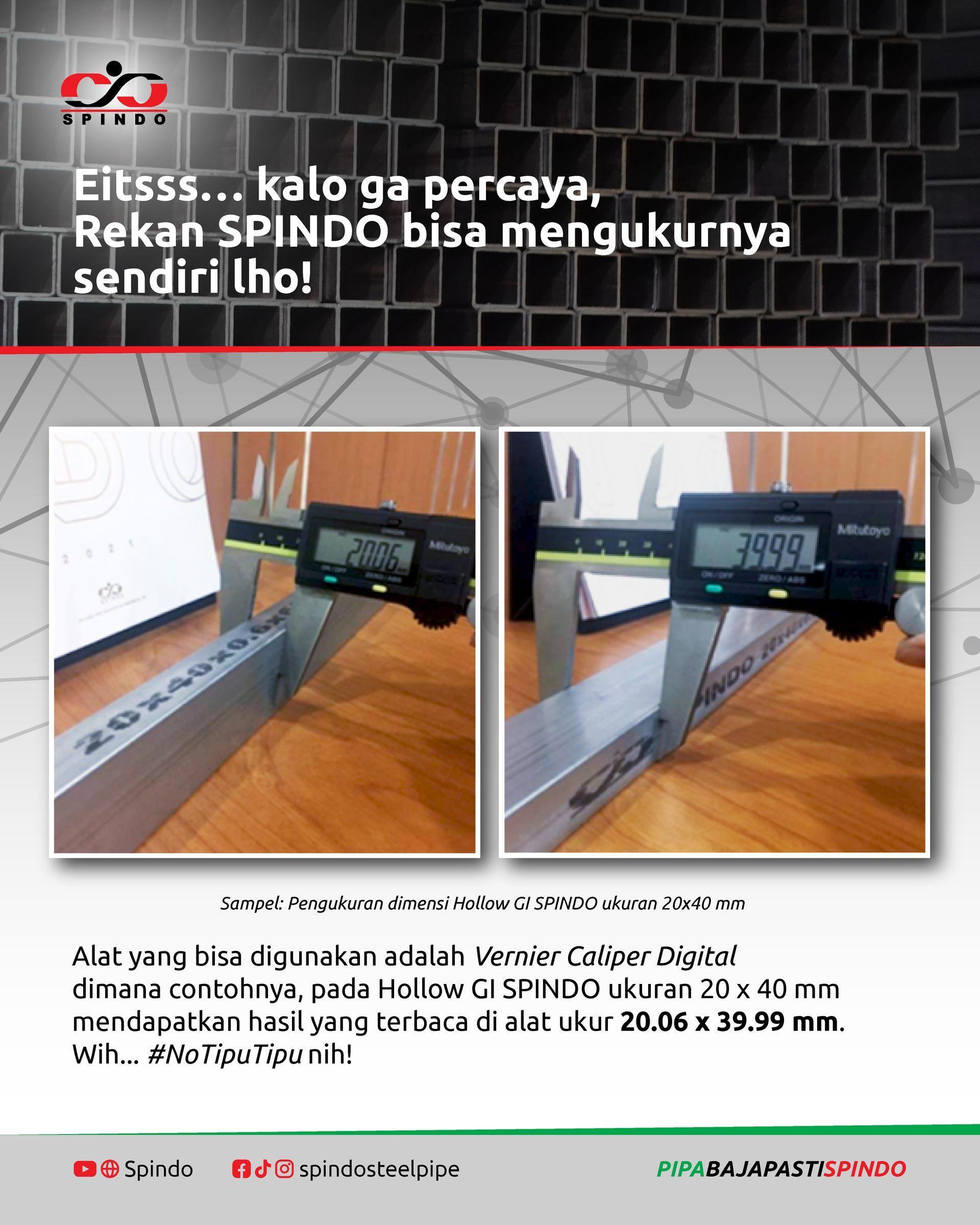

The accuracy of SPINDO Hollow GI dimensions is not just a one-sided claim. By using a

Vernier Caliper Digital

tool, anyone can measure the actual dimensions of the product directly. For example, a 20 x 40 mm Hollow GI SPINDO gives a measurement result of 20.06 x 39.99 mm, which shows high precision and reliable production quality.

Conclusion: Careful Material Selection is a Long-Term Investment

In the world of construction, small mistakes in material selection can have a big impact on the final result. Therefore, it is important to choose Hollow Pipes that are guaranteed accuracy and consistently produced.

By choosing Hollow GI SPINDO, we not only invest in sturdy and precise materials, but also save time, money, and effort in the installation process. Make sure every project runs smoothly from the start by choosing the right product.