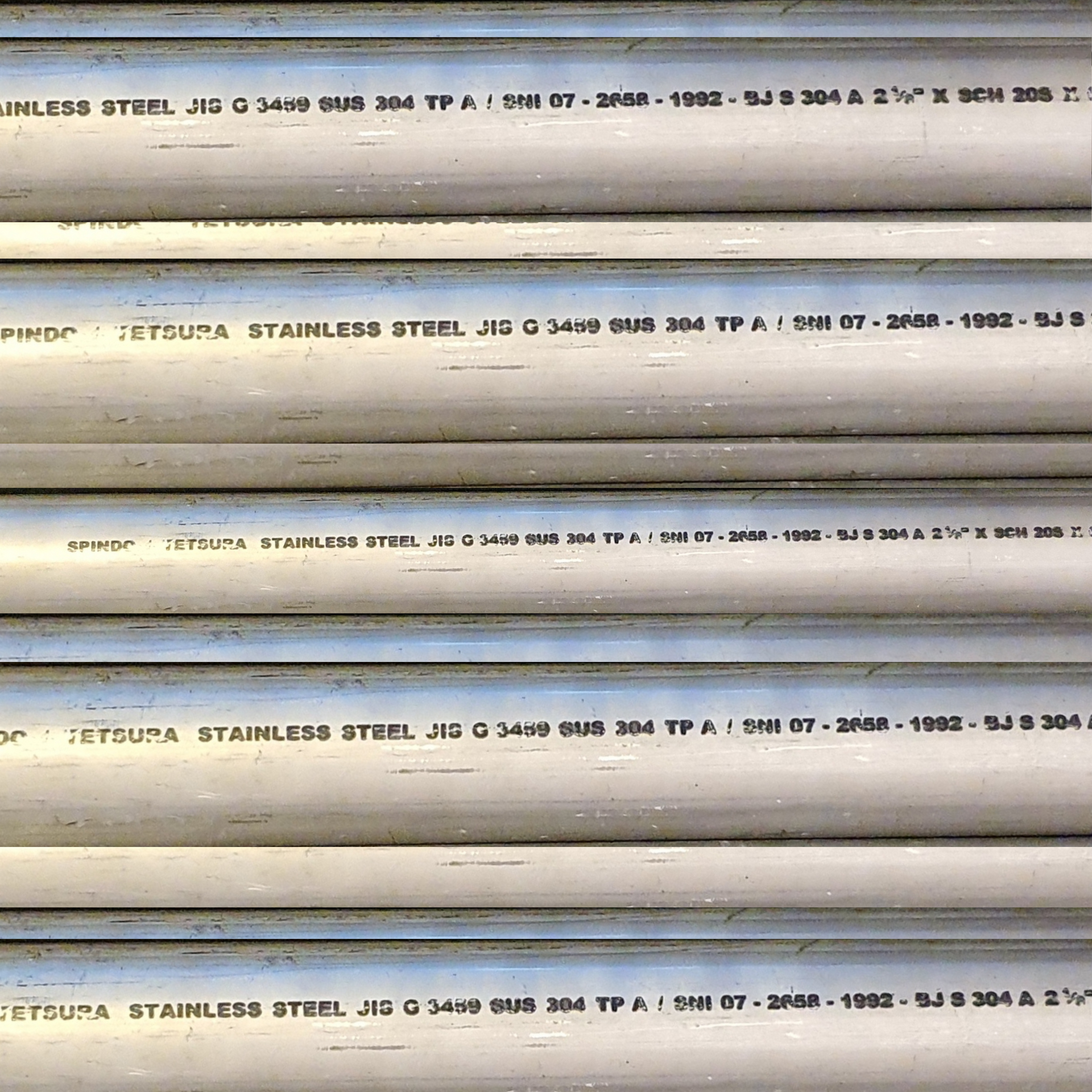

Get to know the "SUS" on Stainless Steel Pipe

This is a subtitle for your new post

In the world of industry and materials engineering, the term "SUS" often appears, especially in the context of using stainless steel pipes. "SUS" can be interpreted as "Steel Use Stainless," and its use refers to a typical type of stainless steel. This article will explain the meaning of "SUS" in the context of stainless steel pipes and review its diverse applications.

Definition of SUS in Stainless Steel Pipe

"SUS" in stainless steel pipe stands for "Steel Use Stainless," reflecting the use of stainless steel. When SPINDO Associates encounter terms such as "SUS 304" or "SUS 316," it indicates the specific type of stainless steel used in pipe manufacturing. Stainless steel (SS) is an iron alloy with a minimum of 10.5% chromium, which gives it high corrosion-resistant and strength properties.

Diversity of SUS Types in Stainless Steel Pipes

- SUS 201, exhibits good corrosion resistance in environments that are generally not very corrosive. Although it is not as strong as some other stainless steel variants, it is suitable for many applications such as home furnishing, automotive industry and construction industry.

- SUS 304, the most common type of stainless pipe, SUS 304 has 18% chromium content and 8% nickel content. It is highly resistant to corrosion and is suitable for applications in high humidity environments, such as the food and beverage industry.

- SUS 316, has the addition of molybdenum, SUS 316 has higher corrosion resistance than SUS 304. This pipe is well suited for applications in the chemical, pharmaceutical industries, and environments with intense corrosion exposure.

- SUS 409, is a ferritic stainless steel that contains other elements such as titanium or niobium, which can improve its mechanical properties and corrosion resistance. This type of pipe is very often used for various applications such as automotive exhaust systems, piping systems and so on.

- Others, besides SUS 304, SUS 316, and SUS 310, there are many other types of SUS with chemical compositions tailored to meet the specific requirements of various industrial applications.

Applications of SUS 201, SUS 304, SUS 316 and SUS 409

The various types of stainless steel materials will certainly make a difference in each use. Each type has unique characteristics that make it suitable for certain applications. Here are some common applications of stainless steel according to its type

Stainless Steel Pipe 201

- Home Furnishings

SUS 201 is often used in the manufacture of sinks and kitchen appliances due to its attractive appearance and adequate corrosion resistance.

- Automotive Industry

Used in the manufacture of mufflers, exhaust pipes, and some engine components that require corrosion resistance.

- Electronic Equipment Manufacturing

Some electronic equipment components that require corrosion resistance can use SUS 201 stainless pipes.

Stainless Steel Pipe 304

- Food and Beverage Industry

SUS 304 is often used in kitchen appliances, piping systems, and food storage containers due to its corrosion resistance and high hygiene.

- Building Construction

Used in the manufacture of stair rails, hand holders, and decorative elements thanks to its aesthetic properties and corrosion resistance.

- Pharmaceutical Industry

SUS 304 is commonly used for equipment and pipes involved in the production and distribution process of pharmaceuticals.

316 Stainless Steel Pipes

- Marine and Coastal Industry

SUS 316 is perfect for environments containing high salt content, such as marine and coastal applications, due to its resistance to pitting and crevice corrosion.

- Chemical Industry

Used in pipes and equipment that interact with aggressive chemicals due to its high corrosion resistance.

- Medical Equipment

SUS 316 is often used in medical equipment that requires high cleanliness and corrosion resistance.

409 Stainless Steel Pipe

- Automotive Exhaust Systems

One of the main applications of SUS 409 is in the manufacture of automotive exhaust systems. This steel can withstand the high temperatures and corrosive conditions of vehicle exhaust gases.

- Piping Systems

Used in piping systems and structural components that require a good combination of strength and corrosion resistance.

- Combustion and Heat Processing Equipment

Used in several applications in the combustion and heat processing industries thanks to its ability to withstand high temperatures.

The selection of stainless steel pipe type should consider the operational environment, temperature, required mechanical strength, and other factors. Although all four types are stainless steel, the difference in chemical composition gives them different characteristics, which can make them more suitable for certain applications.

Now that was a glimpse of understanding of SUS and its various applications, SPINDO colleagues, and of course we can produce the stainless pipes mentioned in the explanation above. If SPINDO colleagues have stainless steel pipe needs as described above, don't hesitate to contact us directly!!!