Indonesian National Standard (SNI) 0039:2013 for Water Pipes as a Complete Guide

What is SNI 0039:2013?

SNI 0039:2013 is the Indonesian National Standard for

carbon steel water pipes, with or without zinc coating (galvanized). It revises the previous SNI 0039:2010 which only covered galvanized steel pipes up to 6 inches. The new standard expands its scope to cover pipes up to

1,200 mm (48 inches) and includes both

black steel pipes (without zinc coating) and

galvanized pipes.

Scope of Application

According to the standard

SNI 0039:2013, these pipes are manufactured by welding (ERW – Electric Resistance Welding or SAW – Submerged Arc Welding) and these pipes are commonly used for:

- Clean water pipelines

- Raw water pipelines

- Plumbing systems

- Fire hydrant systems

- Other water applications (except drinking water)

Galvanized pipes are used for clean water installations.

Black steel pipes (without zinc coating) are used for raw water, plumbing, or hydrant systems.

Types of Water Pipes Based on SNI Thickness Classes

SNI 0039:2013 categorizes pipes into three thickness classes:

- Thin SNI (Light/Lgh)

- Suitable for low-pressure installations

- Commonly used in households or simple piping systems

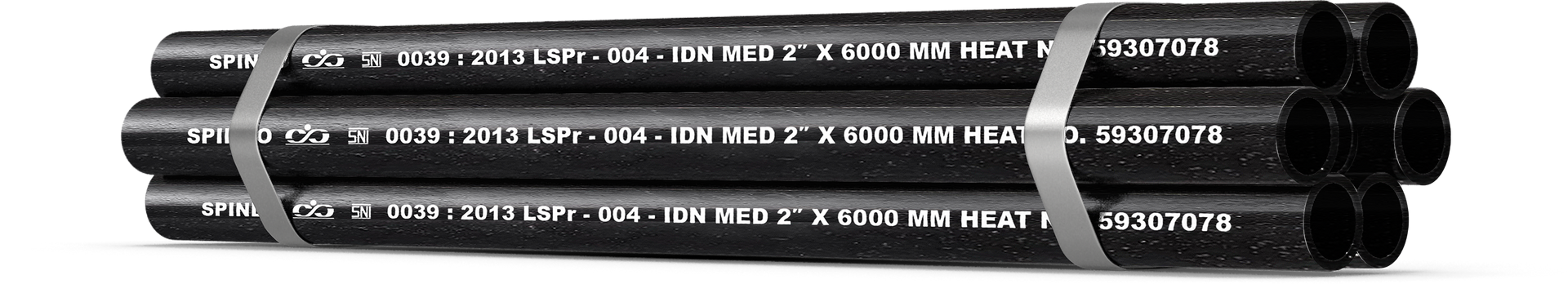

- Medium SNI (Med)

- Used in buildings, factories, or medium pressure installations

- Medium pipes are stronger than thin pipes

- Thick SNI (Heavy/Hvy)

- Designed for high-pressure applications such as industrial plants or fire hydrants

- Constructed for strength, stability, and long-term use

Each class has detailed specifications for

outer diameters, thickness, nominal weight, and tolerance.

Pipe Materials: Black Steel Pipe and Galvanized Pipe

- Black Steel Pipe (without zinc coating): generally used indoors or in systems not directly exposed to weather

- Galvanized Pipe (with zinc coating): coated with zinc (minimum Zn content 98.5%) to resist corrosion. According to SNI, the zinc coating weight must be at least 300 g/m² or equivalent to 42 μm thickness

Quality Requirements in SNI 0039:2013

The standard sets strict quality requirements for water pipes, including:

- Chemical composition: carbon steel pipes must not exceed 0.20% carbon, 1.40% manganese, 0.035% phosphorus, and 0.030% sulfur

- Mechanical properties: tensile strength 320–460 N/mm² (carbon steel), with minimum elongation of 20%

- Strength tests: pipes must pass bending tests, flattening tests, and leakage tests (hydrostatic or eddy current)

- Length: nominal lengths are 6 m and 12 m, with +100 mm tolerance

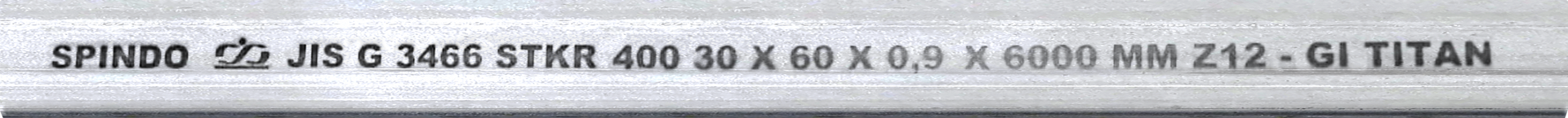

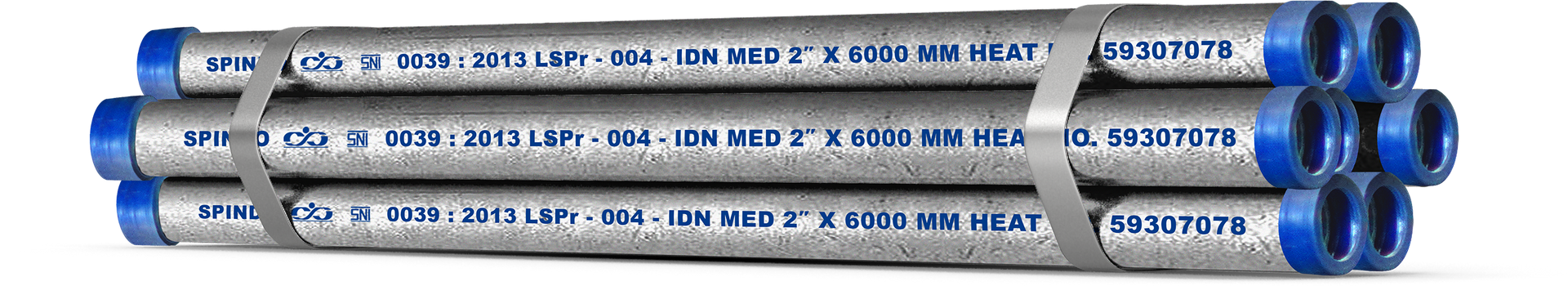

Marking and Identification

All SNI-certified pipes must be permanently marked with:

- Manufacturer’s logo/brand

- Pipe class (Lgh = thin, Med = medium, Hvy = thick)

- Nominal diameter and length

- For galvanized pipes, a colored ring at the pipe end: brown (thin), blue (medium), red (thick)

This marking helps ensure that the pipes used comply with national quality standards. In addition,

SNI pipe markings

are used to guarantee product authenticity and to facilitate identification in the field.

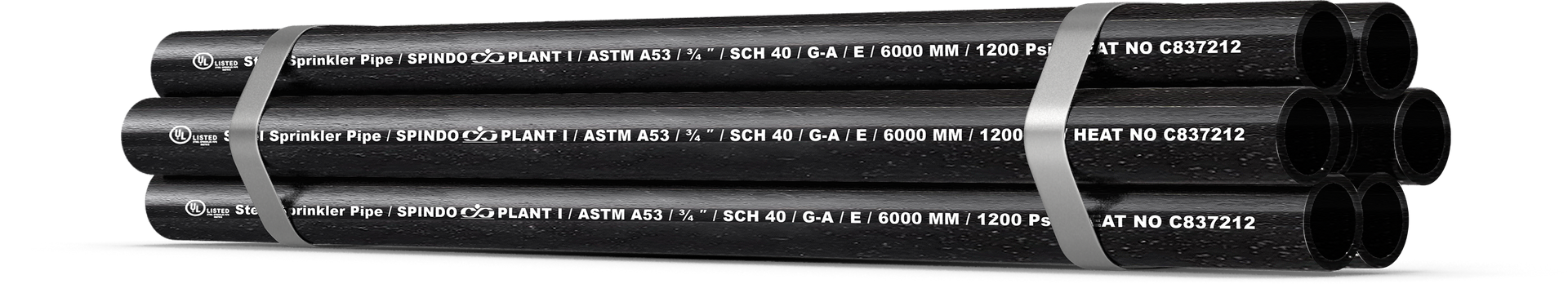

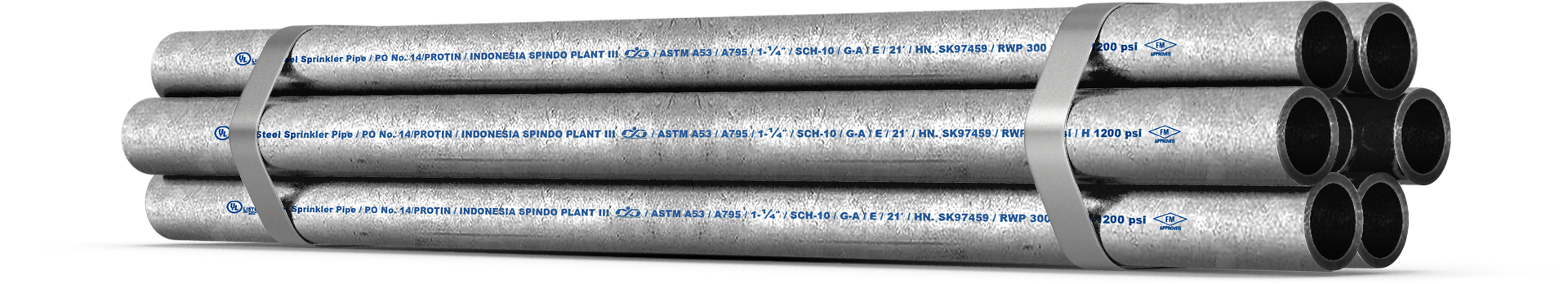

SPINDO Water Pipes and SNI Compliance

SPINDO (PT STEEL PIPE INDUSTRY OF INDONESIA Tbk) is one of Indonesia’s largest manufacturers that produces

SNI 0039:2013 certified water pipes.

SPINDO water pipes are available in:

- Black and galvanized types

- Thin, medium, and thick SNI classes

- Diameters ranging from ½ inch up to 48 inches

The main advantage of SPINDO water pipes is their guaranteed quality, compliance with national standards, and has been trusted in various infrastructure projects in Indonesia.

Conclusion

SNI 0039:2013 ensures that water pipes in Indonesia meet strict standards for

safety, strength, and durability. The implementation of this SNI standard enables consumers and industry stakeholders to identify and select the appropriate type of pipe more effectively, whether for residential installations, building plumbing systems, or large-scale industrial applications.

With extensive experience, modern technology, and a commitment to quality, SPINDO produces water pipes that not only meet national standards (SNI), but are also trusted by the public, contractors, and industry as a strong, durable, and reliable choice.