Pros and Cons of 316 Stainless Steel in Construction

In the world of construction, proper material selection is key to ensuring the reliability and durability of building structures. One material that is often chosen is 316 stainless steel, known for its excellence in a variety of applications. However, as with other stainless grades, 316 stainless steel has advantages and disadvantages that need to be considered. This article will take an in-depth look at the advantages and disadvantages of 316 stainless steel in construction which will help understand if this grade is suitable for your project.

Also read: Stainless Steel 304: A Complete Guide to Its Properties, Advantages, and Applications

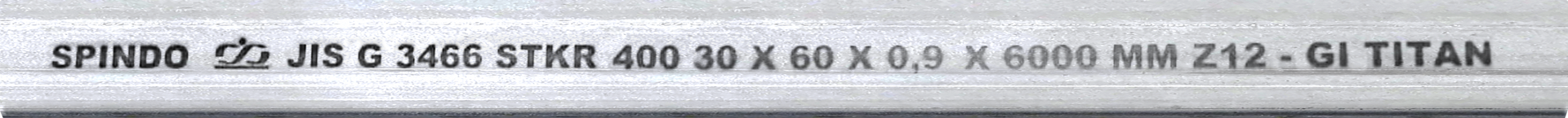

316 stainless steel for factory needs

Introduction

316 Stainless steel is one of the stainless steel grades that is often used in various construction applications. Known for its superior corrosion resistance, this grade of stainless steel has a number of advantages and disadvantages that need to be considered before deciding to use it in your construction project.

Advantages of 316 Stainless Steel

1. Superior Corrosion Resistance

One of the main advantages of 316 stainless steel is its outstanding resistance to corrosion. This is due to the presence of molybdenum in its chemical composition which provides additional protection against aggressive environmental conditions, such as seawater and industrial chemicals. This makes this grade particularly suitable for construction in maritime environments or chemical processing facilities.

2. High Durability

316 stainless steel has a high tensile strength, which means it can withstand large loads without deforming. This property is particularly important in construction applications that require materials with good structural strength.

3. Resistant to High Temperature

This material also exhibits good resistance to high temperatures. Stainless steel 316 will not undergo oxidation or structural degradation at high temperatures, making it an ideal choice for applications involving exposure to extreme heat.

4. Aesthetics and Cleanliness

In addition to strength and durability, this grade is also known for its glossy and modern appearance. This makes it popular for architectural and decorative uses. Additionally, this stainless steel is easy to clean and does not support bacterial growth, making it a hygienic choice for healthcare facilities and the food industry.

Disadvantages of 316 Stainless Steel

1. Higher Cost

One disadvantage is its relatively high price compared to other types of stainless steel, such as 304 stainless steel. The molybdenum content that provides additional corrosion resistance also increases production costs.

Also read: How to Calculate the Need and Price of Stainless Steel for Your Project

2. More Difficult Processing and Workmanship

316 stainless steel is more difficult to work with than plain carbon steel or other types of stainless steel. The cutting, forming, and welding of these materials require specialized equipment and more advanced techniques, which can increase costs and processing time.

3. Greater Weight

Despite its high strength, 316 stainless steel is also relatively heavier compared to some other construction materials. This additional weight can be a negative factor in certain applications that require lightweight materials.

4. Limited Availability

Sometimes, the availability of these grades can be a problem, especially in areas far from industrial centers. This can cause delays in construction projects if the supply of these materials is not easily available.

In conclusion, 316 stainless steel is an excellent material for a variety of construction applications, especially in environments where corrosion resistance and high strength are required. While it has some drawbacks such as higher cost and a more difficult machining process, its advantages often outweigh its disadvantages in the right application. By considering these factors, you can make a more informed decision regarding the use of 316 stainless steel in construction projects.

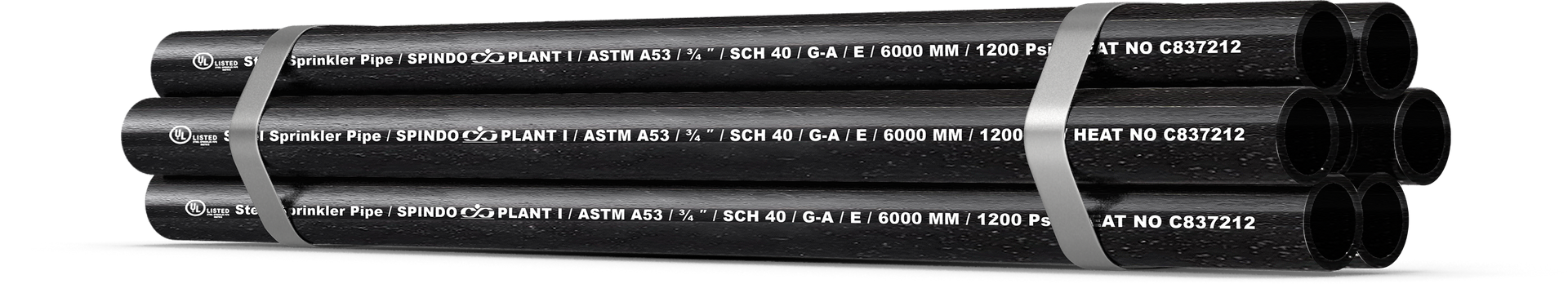

If you need 316 stainless steel for industrial needs, you can buy at SPINDO. SPINDO is a steel pipe manufacturer with the largest production capacity in Indonesia and is experienced in producing various kinds of steel pipes/tubes, including stainless steel. In addition to 316, there is also 304 grade stainless steel which can be used for ornamental tubes used for various daily appliances and industrial pipes that can withstand harsh environments. For reservations or further inquiries, you can click the WhatsApp icon below.